The burning of crop residue in Punjab/Haryana each year causes the pollution levels to rise exponentially each winter, with PM (particulate matter) 2.5 and 10 levels reaching ‘severe’ categorization. According to the WHO, PM 2.5 levels should not exceed 25 micrograms per cubic meter over a 24-hour period and 10 micrograms per cubic meter on average over a year.

But in Delhi, PM 2.5 levels repeatedly surge to almost 1000 in the winter – a figure so high it’s literally off the charts vis-a-vis several pollution monitoring devices. Further, though many think of Beijing as one of the world’s most polluted cities, Delhi’s PM 2.5 levels tend to be about three times the Beijing mean and 15 times the WHO guidelines. This article describes the results of a study on the issue by the India Paryavaran Sahayak (IPS) Foundation, on behalf of the Punjab State Farmers’ and Farm Workers’ Commission.

Rice-wheat (RW) is the primary cropping system of Punjab, covering about 30 lakh hectares during Kahrif season and 35 lakh hectares during Rabi season. The cropping system produces about 20 million tonnes of surplus residues i.e can not manage, of which rice alone contributes 80 percent. The disposal and utilisation of a huge amount of stubbles/straw is a challenge. The problem is magnified for paddy residue due to the short window period for sowing wheat after harvesting paddy.

Until a few years back, the non-availability of suitable machinery was a major constraint in the sowing of wheat in the combine harvested field paddy. With technological advancements during the last decade, options for both surface retention/ incorporation (in-situ) and out of the field (ex-situ) management of straw/stubbles are now available.Central and State Governments are actively working towards solving the problem ofcrop residue burning. Punjab Government has banned crop residue burning and initiated a financial assistance programme to promote crop residue management technologies.

For addressing air pollution and subsidising technological management options for in-situ management of crop residue, a Central Sector Scheme “Promotion of Agricultural Mechanization for in-situ management of cropresidue in the States of Punjab, Haryana, Uttar Pradesh and NCT of Delhi” was launched in the year 2018-19.

The Commission intended to study the farmers’ perception about the scheme itself, understand the scheme’s implementation in the State and identify the areas for improvement in the scheme.

India Paryavaran Sahayak (IPS) Foundation has been working with the farmers in the State on crop residue management for quite some time. Given their connection with farmers, Commission partnered with IPS Foundation to carry out the study with the following objectives:

- Understanding the efficacy of the Crop Residue Management System (CRM) in Punjab,

- Assess motivators to adoption, and

- Understand stakeholders’ views on gaps in the scheme and identify ways for improving its adoption.

The study strives to find drivers, triggers, and barriers for adopting modern technology to move away from the traditional method of stubble burning.

Sample Size

The study is based on primary data collected in the year 2020 from 1348 farmers, 58 CHCs, 50 Primary Agricultural Co-Operative Society, and 20 SMS Combine owners in 11 pre-selected districts of Punjab, covering 271 villages.

The districts for the sample were selected purposively based on a higher number of crop residue burning/fire incidents and area under non-basmati paddy varieties. The number of blocks and villages in each district were selected based on probability proportional to size (PPS) methodology. At a 95 percent confidence level and 6 percent confidence interval, the desired sample size is 255. The study covered 271 villages to have more diversity and representation.

The key findings of the study are as follows:

- The awareness of the scheme amongst individual farmers is universal, and almost everybody knows about the scheme. However, higher awareness is only the dimension that such scheme is being implemented. Nearly half of the farmers donot understand the CRM scheme and know only a few dimensions.

- The primary source of awareness about the CRM Scheme is the Department of Agriculture, KVKs and Panchayats.

- The reach of messages being delivered under the IEC component of the scheme is low. 42 percent of individual farmers have not been exposed to the messages on crop residue management. The strategy for conveying the message is not well defined. 10 different mediums have been used to convey messages, and the impact of a single medium cannot be gauged.

- Training and demonstration under the scheme lacking, which may have impacted the adoption rate. 23 percent of the farmers have attended the training. 45 percent are not aware of the training, and a high percentage does not feel the need for training.

- The participation in the scheme is higher for large operational landholding. The high price of the machines and not getting the desired machine are the primary reason for not participating in the scheme by the individual farmers.

- The satisfaction level among the beneficiaries of the scheme is low. 14 percent of the beneficiaries are satisfied with the scheme. High neutral responses to satisfaction indicate that the scheme has not percolated deep down where it counts. Machine price, high rentals, non-availability of the desired machinery, higher costs, and higher HP tractor requirements are the main reasons for dissatisfaction with the scheme. About 58 percent of CRM users are dissatisfied with the after-sale services of the machines.

- About 50 percent of the beneficiaries are not aware that they could purchase the machines on margin money. The expected delivery time of the machines is 9.5 days, but it takes around a fortnight for delivery and installation of the machines. On average, the subsidy is credited to the beneficiary’s bank account after 40-45 days of inspection.

- The machines purchased through CRM are majorly underutilised. Only 8 percent of the individual beneficiaries rent out the machines, and the average area covered by rented out machines is 31 acres for 2019. The awareness about the mobile applications for the hiring of the machines is relatively low. The average rental per acre during 2019 for supper seeder was Rs. 1876, happy seeder was Rs.1552, mulcher was Rs.1250, and bailer was Rs.1040.

- Despite high awareness, the adoption of CRM technology is low (35 per cent). A large section of farmers is neutral towards the benefits of the scheme. Small farmers perceive that the scheme is to benefit only large farmers.

- Key barriers to adopting the CRM machines available under the scheme are high machine price/rental, higher HP tractor requirements, technical issues ( cannot be used in unlevel filed, making soil harder, apprehension on yield).

- 13 percent of individual farmers are Lapsers, i.e., farmers who used non-burning practice in the first year but adopted residue burning the following year.The primary reasons for abandoning the technology are high rental & fuel cost, no access to a large tractor, immediate payment of rental, non-availability of the required machine (like happy seeder, rotavator), and waiting period for getting the machine.

- Although the use of SMS with combine harvester is compulsory, SMS was not used by 62 percent of farmers. The rate of adoption is less in all the districts. The general perception around SMS is it leads to increased cost, is not suitable for specific soil type and paddy variety (PUSA 44), and non-availability of good quality SMS (grain loss and poor shredding and spreading of stubble).

- The main source of capital for establishing CHC is the contribution by individual members. 26 percent of the CHC have availed of loan for the purchase of machinery from banks and other institutions.

- Half of the CHCs have received training, and the primary sources of training are the Department of Agriculture and KVKs. 31 percent of CHCs who have taken training found it satisfactory. For those who have not taken any training, the main reasons were; felt no need for training and no clarity/awareness on training.

- Half of the CHCs are not aware that they could purchase the machines on margin money. The inspection of machines was not done for 36 percent of the CHCs before crediting the subsidy to them. For those where the inspection was done, the time taken after inspection for crediting the subsidy was 40-45 days.

- For more than half of the CHCs, the machines were delivered close to the harvesting season, due to which they had less time for training and had a high idle time for machines.

- A single CHC covers around 3 villages and has, on average, 3 different types of CRM machines. 88percent of the CHCs provided CRM machinery on rent to the farmers. In 2019, each CHC received 35 enquiries on average, of which only 19 were serviced, i.e. 46 percent of enquiries received by CHCs went unserved.

- In 2019, the area covered by the CHCs increased by 128 per cent (12746 acres) compared to 2018 (5584 acres). The total area for which the machines were rented out in 2019 was 8809 acres compared to 2057 acres in 2018.

- The significant challenge while renting a machine is the higher demand for a particular machine and its limited availability. For CHC, delayed payment from the farmer is an issue. 60 percent of the due payment to CHCs were made within a month. Only 16 percent of rentals are received as instant cash, and just about 3 percent of the receivables became bad debt.

- A majority of PACS (60 percent) are “neutral” in satisfaction level regarding participation in the scheme. Similarly, a higher percentage of PACS are ‘neutral’ on the effectiveness of the scheme. Some of the PCAS is of the view that the CRM Scheme is non-beneficial.

- The High costs, poor support by the manufacturers and non-availability of the desired machinery are the other significant issues with the scheme. The delayed deliveries of machines is a major issue in purchasing by PACS.

- 42 percent of PACS did not receive any training for using the CRM machinery. The main source of training for the PACS is KVKs. The satisfaction level with the training is relatively low.

- Each PACS received on an average 70 enquiries for custom hiring, of which only 54 were serviced, i.e. 23% of enquiries received by PACS remained un-serviced. The number of hours the PACS rented the machines increased in 2019 compared to 2018, and the same is the case with the number of machines available.70 percent of the PACS do not have any targets for utilising the machine. Those that acknowledged having fixed targets found it hard to achieve. The utilisation of Rotavator, Zero Till, and Happy seeder is higher compared to other machines. Average earning is approx. Rs.80,000 for the respondent PACS. Some of the machines with PACS are grossly underutilised.

- Theprimary reasons for not taking the machine on rent is the non-availability of desired machines and not having a large tractor at their disposal. A majority of PACS viewed that farmers could not afford the rental amount and that due to a lack of operational skills, the farmers avoid taking machines on rent.

Key Takeaways

- The study highlights the need to reinforce the financial and non-financial advantages of crop residue management.

- The shift from burning to the usage of machines for residue management in the eyes of farmers is low and less pronounced as a majority are still fence-sitters indicating the benefits of machine use are not sharp and clear.

- There is a consensus emerging among farmers, CHC and PACSs that there is no negative impact of technology on crop and yield.

- Training plays an important part in the adoption of machines for residue management. Once farmers are trained to manage the fields more scientifically, technology will achieve better outcomes.

- The biggest hurdle for usage is access to desired machines in the time of need. It is essential to streamline access and linkage to machines for small farmers. CHC and PACS have to play a more significant role.

- Enforcement and effective monitoring are necessary to ensure serious off-take/adoption of machines for residue management.

- Full awareness of the scheme and payment options should be provided to all the stakeholders.

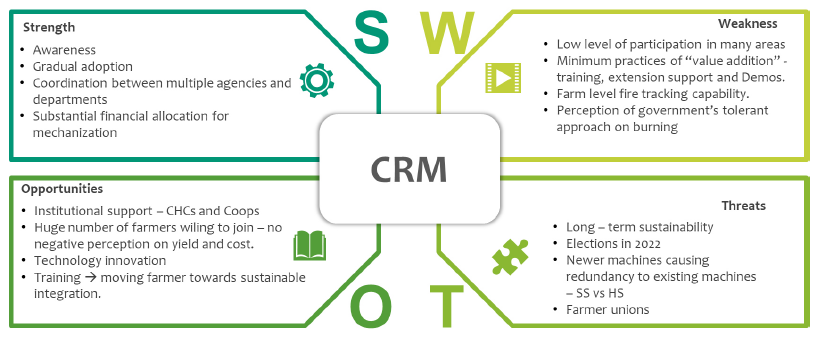

SWOT Of CRM Scheme:

Source: Field Survey

Factors That Can Limit Burning:

Farmers were forthcoming in their suggestions that can help limit paddy residue burning practices in their areas, top suggestions are:

- Reducing price/rentals of machines,

- Improving the availability of the desired machine by encouraging CHCs, PACS to increase their machine utilisation,

- Just about 8% of the individual farmers rented out their machines (Rotavators, HS, and ZTD), covering an average of 6 farmers/machine and 31 acres /machine. One way to increase machine usage and adoption is by encouraging rental participation from individual machine owners, thus improving machine reach to a larger section of needy farmers.

- Conducting better training and extension support/handholding of farmers.

It should be noted that farmers in no way resonate with cash incentives (Rs 100/qtl incentive) and the fear of Government enforcement action figured low (due to limited action in the past).

Way Forward

Based on the findings of the study, a two-pronged approach is suggested (Table 1) –

- a) Steps that need immediate focus,

- b) Steps that are required to be done during the season.

Table 1: Steps needs to be taken by the government

| Key Deliverables | Immediate focus areas | During the season |

| Reinforce Government Seriousness | ||

| ● Strict enforcement of SMS adoption with Combine harvesters

● Enforce machine utilisation by all CHCs to ensure maximum renting outside the group ● Special check on all Combine operations (with SMS) and burning instances in mid-September. This period sets the mood for burning or non-burning. |

1.1.1 | 1.1.2 |

| Improve Coop and CHC machine utilisation tracking – what gets measured, gets improved | ||

| ● To improve accountability, machine usage monitoring system/platform should be implemented for CHC and PACS machines.

● Set season-specific machine utilisation targets for CHC/PACS.

|

1.1.3 | 1.1.4 |

| Enhance Machine adoption | 1.1.5 | 1.1.6 |

| ● Conduct a detailed study (block/village level) around the spread of existing machines vs fire instance – identify gaps and prioritise fresh allocation of machines.

● All applications to be cleared, orders issued and installation TAT to be ensured. Machines should be on the ground by 15th September. ● Promote the purchase of machinery by paying ‘Margin Money’ ● Price reduction – GST Waiver/Reduction |

1.1.7 | 1.1.8 |

| ● Panchayats/Sarpanch to be made accountable for burning counts in their villages.

● Enhance field level fire count monitoring and reporting – Village/farm boundaries to be mapped in the remote sensing platform for sharper monitoring. |

1.1.9 | 1.1.10 |

| Improve Service Support from Manufacturers | 1.1.11 | 1.1.12 |

| ● Streamline the machine delivery process – cut down on machine delivery time.

● Periodic machine check – ensure field calibration and problem-free operation – seasonal machine melas’/service camps at village clusters/PACS. |

1.1.13 | 1.1.14 |

| Training/Capacity building & Farmer handholding | 1.1.15 | |

| ● Increase training frequency in high burning villages. Use technology for wider reach (especially during restricted field activities), e.g., Zoom, WhatsApp, YouTube, VCs.

● Training schedule to be widely advertised. ● Build consistency in content. Training should focus on technology benefits, clarify myths, experience sharing, cost-benefit, and ease of operation. |

1.1.16 | 1.1.17 |

| ● Create ‘VatavaranSahayaks’ with IEC funds – capacity building for village volunteers in all aspects of residue management – train the trainer and build community engagement. | 1.1.18 | 1.1.19 |

| Improve Usage of App for machine visibility to farmers | 1.1.20 | 1.1.21 |

| ● Finalise which app to be promoted and with what features – Centre/State developed

● At every training/demonstration, farmers to be encouraged to download the app on their phone |

1.1.22 | 1.1.23 |

| IEC campaign/mapping | 1.1.24 | |

| ● Create full-year Information, Education and Communication [IEC] plan

● Standardise farmer communications – communication should bring out the region-specific value proposition, address the myths and misconceptions of farmers related to technology. ● Promote success stories, invite progressive farmers who could influence. |

1.1.25 | 1.1.26 |

Source: Field Survey

Proposed Improvement in the Scheme

Based on the interactions with farmers and their feedback during the survey, the following improvements in the Scheme in the coming season.

- Scheme timelines: The entire process from the scheme’s announcement, application, approval, and delivery should happen well in time. Farmers should get enough time to plan their season, promote their services/machines, align fellow farmers for rental, and plan training. The machines should be delivered to the farmers by 15th September positively.

- Flexibility to choose a machine mix:Farmers/CHCs/PACS should be given the flexibility to choose any mix of machines from the bouquet.

- Targets for the district:Targets should be fixed after reviewing the spread and usage of existing machines. Fund allocation should be aligned accordingly.

- Robust technology platform:A technological platform covering all the steps of implementing the scheme should be developed. The registration of farmers, inviting of applications and distribution of subsidy should be through the platform. The platform should be interactive so that any farmer, if facing a problem, can use it and interact with the officials.

- Formation of groups / CHC: The Formation of farmers groups is very informal; the platform created to register the group had operational issues. CHCs should have a control/ tracking (coding) process; a parallel can be drawn with the registration and control process for registering farmer clubs (by NABARD) or Self-Help Groups.

- Appraisal of new CHC application: There should be an appraisal process – the local agriculture officers should review CHC application against predefined parameters like experience in machine renting business, the mix of members and profile, rental potential, willingness to deliver the desired targets, adhering to reporting requirements to identify the actual target groups.

- Performance of existing CHC: Thetargets for CHCshave not been reviewed at any stage, resulting in most groups not performing as per CHC guidelines. There should be some mechanism for performance reviewing of existing CHC’s.

- Direct Beneficiary Transfer:The subsidy should be transferred directly to the beneficiary’s account without any delay. The time taken for physical inspection should be reduced so that the subsidy is transferred at the earliest to the beneficiary.

- Pricing of machinery:Farmers claimed significant machinery price increase immediately after scheme announcement. A market study should be done to look for ways to rationalise prices.

(Courtesy- Punjab State Farmers’ and Farm Workers’ Commission)

Mr. B.S. Sidhu is Commissioner, Agriculture, Punjab and Mr. Ritesh Bhatia is CEO, India Paryavaran Sahayak (IPS) Foundation. The IPS Foundation is a not-for-profit entity incorporated under Section 8 of the Companies Act. IPSF comprises promising, young, environmentally conscious individuals who come from varying business fields and have a shared vision of shouldering the responsibility as individuals and as an entity to protect and support all endeavours that are environmentally progressive. IPSF works closely with farmers to generate awareness around the ill effects of stubble burning, on available technologies to manage crop residue without burning, and prevailing government schemes. It educates and traina them on the use of these multiple technologies to improve the adoption of non-burn practices.